Third Custom Rifle Build

Marlin Action

Green Mountain Barrel

Caliber 222 Remington

Start Date: 3/22/2019

Completed: 3/31/2019

Like most projects, it takes longer to plan and set up than it does to actually

do the work. I bought a used reamer and gauges off Gun Broker at least a year

ago. Advertised as 222 Remington with 3 gauges (NO-GO, Field & GO). The

price was right, the gauges were right but the reamer was wrong. The reamer was

actually a 222 Rem Mag.

Not a big deal, I wasn't ready to start anyway. So I

looked around online and found a used Clymer reamer in 222 Remington. Sold the

222 Rem Mag reamer to a customer.

Not sure when the Boyd's stock showed up, at least last fall maybe even farther

back than that.

Once again I bought a Green

Mountain Barrel for this project and as in the past their service was

great.

I had already faced off the receiver and lapped the bolt lugs so that much was

out of the way.

Problems on the 2nd rifle chamber prompted me to learn exactly what went wrong

and why. Discussing the problem with a couple of new contacts it came to light

that I had not properly adjusted my steady rest. In short, it simply was not

holding the barrel tight enough.

Understanding that improved things dramatically. So much so that on this

project a fired round from the new barrel leaves the brass so close to original

dimensions that itís amazing for a 50 plus year old lathe.

I did not taper the new barrel but instead turned it down to just over an inch

in diameter.

As with the 1st two rifles I once again locked this rifle into my Tipton gun

cleaning vise, tied a string to the trigger, tossed a pair of heavy insulated

coveralls over the action and backed away with the string. The barrel wouldn't

fit a sythetic stock so I test fired it assembled

into the Boyd's stock.

That's fine, call me chicken, but I'm not the least bit interested in finding

out the hard way that screwed something up. There are just too many steps to

this process for me to leave anything to chance.

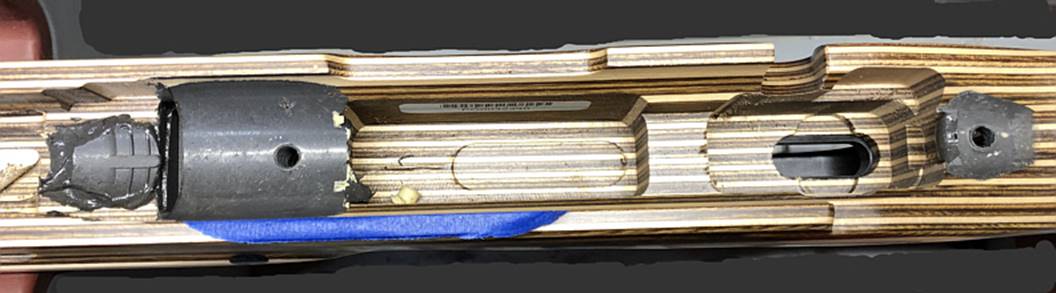

This rifle would become my first bedding project before I took it to the range.

It involved watching several videos and doing my best to understand the

procedure before attempting such. The two "must watch" videos for me

turned out to be these two:

First

Second

It turned out great and went like the videos said it would.

Had a little trimming to do but that took all of 5 minutes.

At the range on March 31st. Burning up some old factory ammo, I went through

the same fire 3 and clean procedure as I always do and then took it inside to

my cleaning bench for a thorough cleaning.

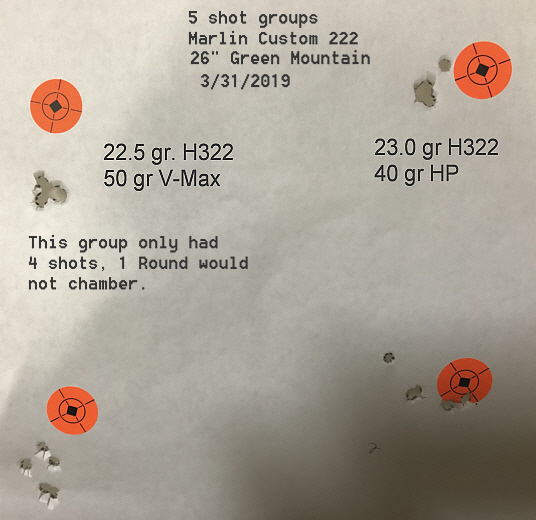

Next I loaded 4 groups of 5 rounds using H322 powder. 10 rounds with 40gr. HP

bullets and 10 with V-Max bullets. Made it back down to the range on April 6th.

All of the rounds were loaded in new Winchester brass. I did not full length size, just ran the cases over the expander ball

to remove any dings in the case mouth. On the one round that did not fire, the

shoulder was out of spec by 6 or 8 K.

I am thrilled with the performance of this rifle. Like the first two rifles the

Green Mountain Barrel performance is amazing at a fraction of the cost of other

barrels on the market.

There are several powders that work well in the 222 and eventually I will try

other powders but for now I'm content with the H322 powder.

I intend to put a high gloss finish on the Boyd's stock on this rifle but not

sure when that will happen.

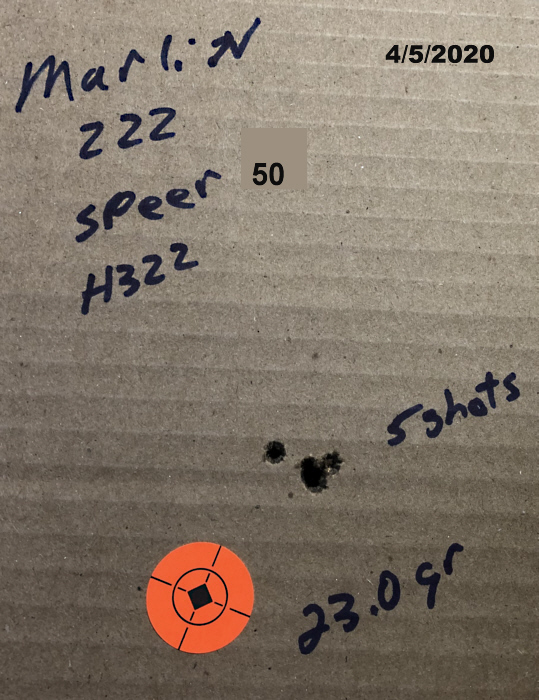

Update: 4/2020

Working with some new bullets for this years Prairie Dog trip out west. Speer 50 Grain TNT HP. Think it's going to be fine.