First Custom Rifle Build Page 3

Marlin Action

Green Mountain Barrel

Caliber 17 Fireball

May 27th, 2015

Very early in this project I began the process of picking a caliber. That was mind boggling but only because I let it be. I read everything I could think to read. Researched ballistics until I was cross eyed and started coming to a decision.

I crunched numbers and looked at ALL of the variables. For instance; How much velocity do I get per grain of powder? In other words in my mind, how efficient is this cartridge compared to that cartridge.

I was comparing:

17 Hornet

17 Fireball

17 Remington

20 Vartarg

20 Tactical

204 Ruger

And even looked at the 6x45, 6x47 and a couple of others I can't think of off the top of my head.

Why look at all of these?

Because we can !

If I am going to order a reamer and drop that chunk of change, I want to be happy with my choice. When I'm done with this project, I want to be excited about the cartridge I picked and I want to be able to try as many reloading options as possible.

When you look at the list of cartridges, you can see that they all share the common ground of Light and Fast.

Using Average Velocities from reloading manuals, I came up with efficiency numbers and cost per round numbers and the list goes on and on. There really wasn't any place to stop so I forced myself to stop anyway.

I have been amazed by the performance of the 17 Hornet and the 204 Ruger so I wanted to play ball in that park. But out there in the middle you start splitting hairs and I'm sure it becomes a personal opinion.

I decided on the 17 Fireball and placed a call to Manson Reamers. They were incredibly helpful I enjoyed discussing my options with people who know their business. I ended up buying a floating reamer holder and a 17 Fireball finish reamer. Additionally they encouraged me to get my hands on the book titled "The Complete Illustrated Guide to Precision Rifle Barrel Fitting" mentioned earlier. They sell the book and rather than spend time shopping around, I had them send it with my order. Their service was everything you would expect and then some. Well packaged, prompt and accurate.

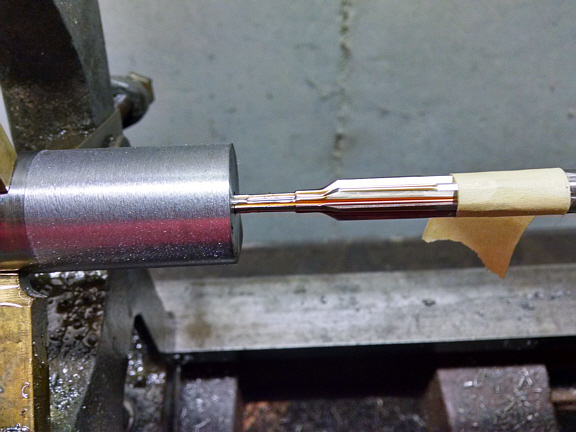

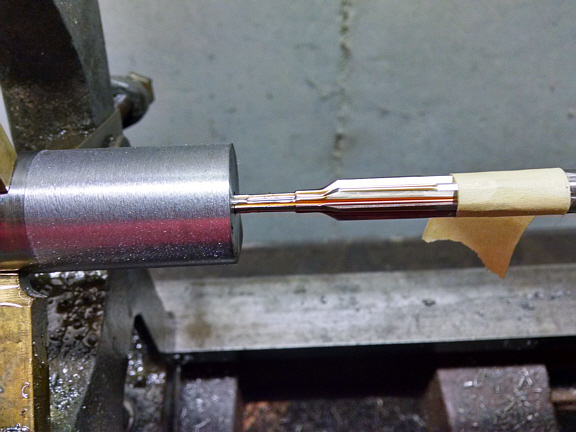

Finally on May 24th I was ready to ream the chamber. I started about 9:30 PM and finished a little before 11:00. It was as expected, a very slow process but it required constant attention so it seemed faster.

Basically it was; coat the reamer with cutting oil move ahead to cut 1/32 of an inch. Back the reamer out, clean it off, re-oil and cut another 32nd. Really happy I went with the 17 Fireball at this point. It's a short cartridge!

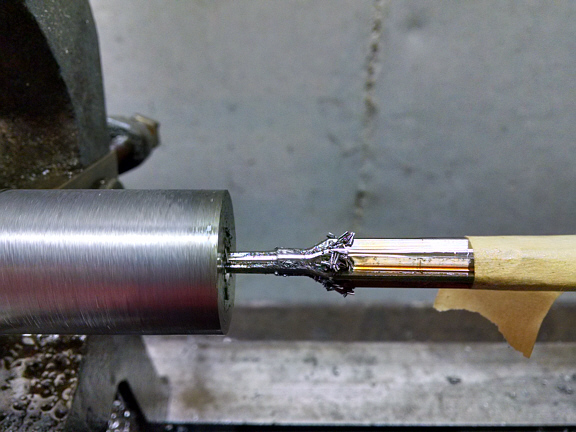

I stopped 30 thousandths short as recommended. Moved all that tooling out of the way and prepared to thread the barrel shank. Once again, what was going well turned to crap. I won't even try to explain it at this point, let's just say I hit a burm in the learning curve.

I do have to admit that I've heard my Dad's voice several dozen times on this project. He spent 40 years of his life telling me to be patient and I still hear it ringing in my ears. But that's a good thing because I did finally start listening to him so I haven't destroyed anything yet. And all by myself I figured out to just STOP, figure out the problem and forge ahead rather than getting a bigger hammer. But I think I understand how the term hammer forged barrel came into play.

Bill

Page 1 Page 2 Page 4 Page 5 Page 6